What I’m exploring

I’m exploring the intersection between manufacturing, labour shortages, and ML. My short-term goal is to speak with others and learn more about manufacturing, automation, and ML. In the medium term, I want to assemble a team of people interested in solving a hard problem in this space. My ultimate goal, to borrow a phrase, is to “choose a good quest” and build a company at this intersection.

In the most simple terms possible: a good quest makes the future better than our world today, while a bad quest doesn't improve the world much at all, or even makes it worse.

Trae Stephens and Markie Wagner, Pirate Wires 1

Some of the questions which guided me in this direction:

- What might happen if global supply chains broke down?

- What did the Covid-19 pandemic reveal about our supply chain resilience?

- What are the likely consequences of declining birth rates?

- What are the potential implications of frosty relationships between economic superpowers?

- What conditions must be true for most of the world's products to be automatically produced?

- How might manufacturing change in the coming decades?

Through research and personal experiences, I have concluded that more STEM talent should be tackling hard problems at the intersection between manufacturing, automation, and ML.

How I got here

To date, I've built software and internet companies. They include Foro (software/AI automation), Purepoint (bespoke software engineering), Bowhurst (e-commerce), and Mighty Matcha (e-commerce).

When building my first company, I never once considered that it was only possible to create because others before me built great technologies and systems. Consider something as ubiquitous today as a computer. It's made up of many parts, designed, manufactured, and assembled in different countries, shipped across the globe, transported and placed into a warehouse, delivered to a store, and finally sold to me so I can code and build. That supply chain didn't just happen overnight; it took decades. It required people to collaborate and solve many hard problems along the way.

We needed to make physical things for the Internet era to be a possibility. I don't want to be Captain Obvious, but this point is worth stressing. If manufacturing is constantly disrupted, you won't be grilling meats with Zuck in the metaverse anytime soon. Likewise, Elon doesn't get his crater-view retirement pod on Mars unless STEM talent finds manufacturing a sexy career.

I think that globalisation gave North America, Europe, Australia, and New Zealand – I'll henceforth refer to them as 'the West' – a collective amnesia about the importance of making physical things. Brexit, the Covid-19 pandemic, the Ukraine war, inflation, and geopolitical tensions seem to be awakening the West to the importance of supply chain resilience.

Nations are waking up. The US is undergoing a huge reindustrialisation project partly due to the Inflation Reduction Act 2022 and the CHIPS Act 2022. The UK announced a new semiconductor strategy in May 2023. The European Parliament recently approved the European Chips Act.

Relying on other nations to produce components critical for your national security is flawed. We got into that situation because we got comfortable, and its cheaper. Imagine the goods we're going to need to produce at home as a prerequisite to us reshoring other, more complex products.

In Defence the fragility is borne out of decades of emphasis on prioritising cost savings and focus on efficiency gains. Whereas for industry, we’re seeing the impact of upstream events and points of failure reverberating across highly interconnected and globalised supply chains. Continuous, externally driven issues with current systems and structures have resulted in a ‘new normal’ of constant disruption.

Major General Simon Hutchings, November 2022, Defence Supply Chain Strategy, Ministry of Defence 2

Constant disruption is the new normal – that's my belief. I don't know for long that will be true, but I think we're talking decades, not years. Reshoring will require us to rethink the way we manufacture goods so that they can be reliably produced at the right price. This will present plenty of problems for entrepreneurs to tackle.

What might be possible when we reshore manufacturing?

This is an exciting question to entertain because it reveals so many hard problems available for entrepreneurs to tackle. Traditionally, companies outsource because of cost, availability of labour, and access to specialised knowledge. Entrepreneurs looking at reshoring will need to systematically address each of those points. Here are some starting points for further exploration:

- Could advances in production techniques, automation, and ML lead to factory configurations that are more versatile, thereby reducing total machinery costs?

- How might AI help us to design different methods of production?

- Which forms of automation would offset the higher onshore costs of labour?

- Given current technological constraints, where is the optimal balance between manual and automated production? How many existing companies know their own optimal balance?

- Which breakthroughs are required in automation and ML to build fully automated factories for an ever-increasing number of goods?

- Could you apply software and internet business models to manufacturing? e.g. Subscribe to access guaranteed machine time or real-time variable pricing based on raw material and energy costs.

- Could you fully automate the reverse engineering process and produce a part without infringing IP?

- Could you build a network of microfactories closer to the end consumer of the goods they produce, and have them specialise in the most in-demand intermediary goods in that region?

- How could you optimise the energy usage within a factory?

- What about controlling the emissions produced?

- Could an AI consume the latest research on materials science, manufacturing techniques, and production methods, and make decisions about how a factory should function?

Constraints are sometimes a blessing – they focus the mind on developing creative solutions to problems. There are incentives in all directions for entrepreneurs in this space.

Why am I curious about labour shortages?

In the first paragraph, I mentioned labour shortages. The pandemic provided a moment of pause and reflection for many people. Some took early retirement. Others decided to change careers.

Demography can reveal a lot about the anticipated future of a nation. Here are some recent stats I've learned:

Retirement

- About 10,000 people retire daily in the US. 3

- The final people belonging to the Baby Boomer generation (born 1946-1964) will reach retirement age in 2031.

- The peak of the baby boom era was 1960, therefore, daily retirements will peak in 2025. 3

- As their generational name implies, they were the largest generation.

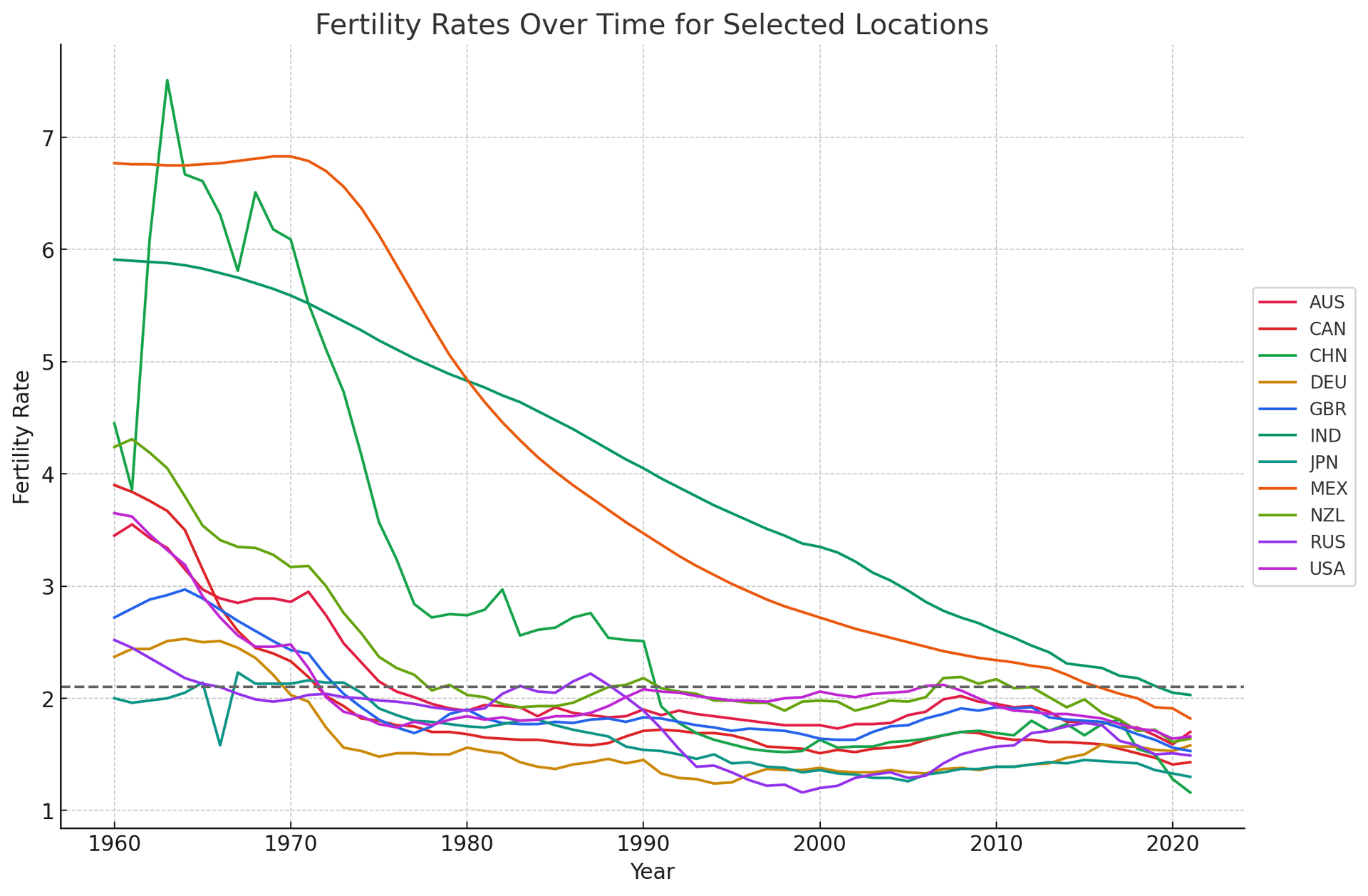

Fertility Rates

- A fertility rate of 2.1 children per woman ensures a stable population. 4

- This assumes no net migration and mortality rates remain the same.

- China is facing demographic collapse. Its population will halve by 2100. 5

- The world population is expected to peak at just over 10 billion around 2100. 6

- Some European nations are projected to lose 10-15% of their people by 2050. 6

- Fertility rates have been below repopulation levels for several decades in many of the following countries:

A total fertility rate of 2.1 children per woman ensures a broadly stable population. This assumes no net migration and unchanged mortality. Data for South Korea, Singapore, and Ukraine was unavailable to plot from this dataset.

| Country | Fertility Rate (2021) |

|---|---|

| India | 2.0 |

| Mexico | 1.8 |

| United States | 1.7 |

| Australia | 1.7 |

| United Kingdom | 1.6 |

| Germany | 1.6 |

| New Zealand | 1.6 |

| Russia | 1.5 |

| Canada | 1.4 |

| Japan | 1.3 |

| Ukraine | 1.2 |

| China | 1.2 |

| Singapore | 1.1 |

| South Korea | 0.8 |

When I consider the above data, here are the kinds of thoughts I have about manufacturing and automation:

- What industry knowledge will be lost when the Baby Boomers retire? How many owner operated manufacturing SMBs haven't digitalised all of their knowhow?

- If nations reshore, how will they handle labour shortages in the manufacturing sector? Will subcontracting of parts give way to full production by one company?

- Will we have enough people to do the research, science, and engineering required to make major breakthroughs in automation? Aren't we in a race against time type situation?

- How will finance evolve in an era of record retirement, ageing populations, the largest ever intergenerational wealth transfer when Baby Boomers die, and worker shortages?

- How likely is it that certain nations will offset their declining populations with mass immigration? Will people within those nations understand the necessity and be open to mass immigration?

- Fewer people in an economy typically means less consumption. Could a reshored factory designed for fewer end users operate differently? For example, what about agile factories capable of theoretically producing millions of different products in smaller quantities in contrast to a traditional production line method of making millions of a single product.

- With a smaller workforce, isn't the widespread adoption of robots a necessity?

- The five nations with the highest robot density – measured as the number of industrial robots per 10,000 workers – are South Korea (0.8), Singapore (1.1), Japan (1.3), Germany (1.6), and China (1.2). 7 Fertility rates, shown in brackets, are all below repopulation levels.

Why I care

I believe that we have a moral obligation to contribute positively towards the future for humanity. The intersection of manufacturing, labour shortages, and ML presents so many fascinating problems for entrepreneurs to tackle. I think this intersection represents a good quest!

Let's not forget how to build things. The industrial base is essential for progress. In an era where software companies dominate headlines and the bulk of venture capital flows in that direction, it's refreshing and inspiring to see creators who can bring together brilliant teams to tackle hard industrial problems. I've seen examples recently in the US, such as Varda Space Industries (Space Factories and Space Drugs!), Figure (Humanoid Robots), Machina Labs (Agile Manufacturing), Hadrian (Efficient Factories), Radiant (Portable Nuclear Microreactors), and in the UK, companies like Space Forge (Space Manufacturing). These companies are building physical things, daring to reinvent how things are done, and in some cases, inventing entirely new markets.

How you can help

I'd like to meet others who want to work or fund companies in this space. In particular, I'm looking for the following:

- Discussions with people working at the intersection of manufacturing, robotics, and ML.

- Discussions with VCs who are passionate about this topic.

- Opportunities to shadow senior executives of companies building physical things in this space.

- Introductions to startups and early-stage companies.

- Introductions to others interested in starting a company.